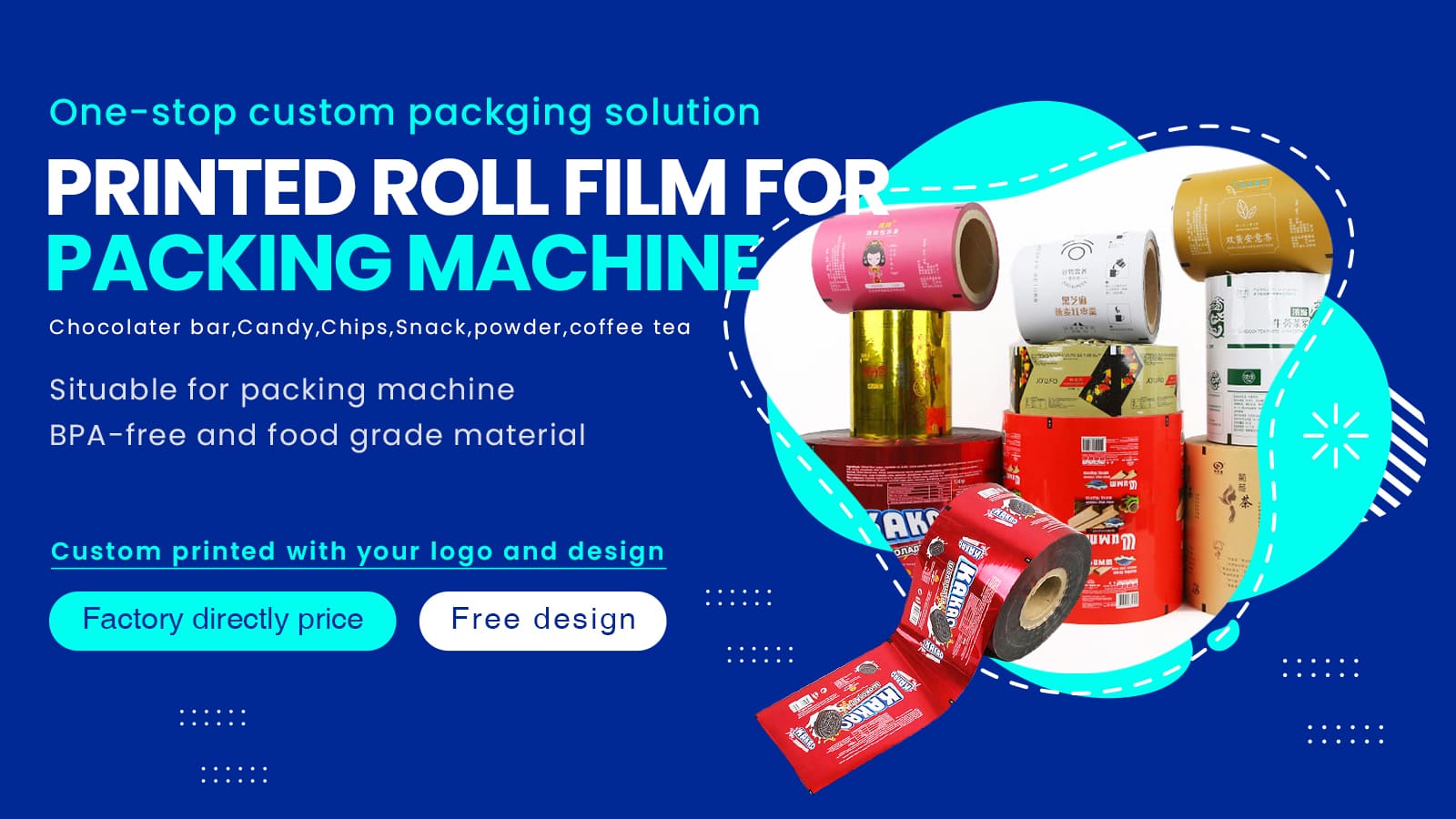

Printed roll stock is a popular form of flexible packaging that is widely used in the food, beverage, and pharmaceutical industries. It is a continuous roll of film that is printed with high-quality graphics and text, which can be used to wrap a variety of products. Printed roll stock is typically used with a packing machine, which seals and cuts the film to the desired length.

Application

The printed roll stock film can be used to create various types of packaging, including bags, pouches, and sachets. It is often used to package dry and wet products such as candy,chocolate bar,chips,popcorn,coffee, pet food, and personal care products.

Cookie roll film

Chocolate bar roll stock

Chips roll film

Powder roll film

Custom Printing

The printed roll film allows for high-quality printing of graphics and text, which can help to promote a brand and enhance the product's overall appeal.It also can be customized to fit the specific needs of a product, such as the size and shape of the packaging.

Barrier material

Printed roll stock film are laminater with couple layers of plastic or paper film,which provides excellent barrier properties that protect the product from moisture, oxygen, light, and other environmental factors. This helps to extend the shelf life of the product and maintain its quality.

Using Printed Roll Stock with a Packing Machine:

Printed roll stock is designed to be used with a packing machine, which allows for efficient and accurate packaging of products. The packing machine works by pulling the film from the roll and feeding it through a series of rollers, which seal and cut the film to the desired length. The product is then placed on the film, and the machine seals the film around the product to create a secure package.

There are several different types of packing machines that can be used with printed roll stock, including vertical form fill seal (VFFS) machines, horizontal form fill seal (HFFS) machines, and rotary fill seal machines. VFFS machines are ideal for packaging products that are in a vertical orientation, such as snack foods and candy. HFFS machines are better suited for products that are in a horizontal orientation, such as bread and pastries. Rotary fill seal machines are used for high-speed packaging of products, such as pills and tablets.

Tips to order printed roll films

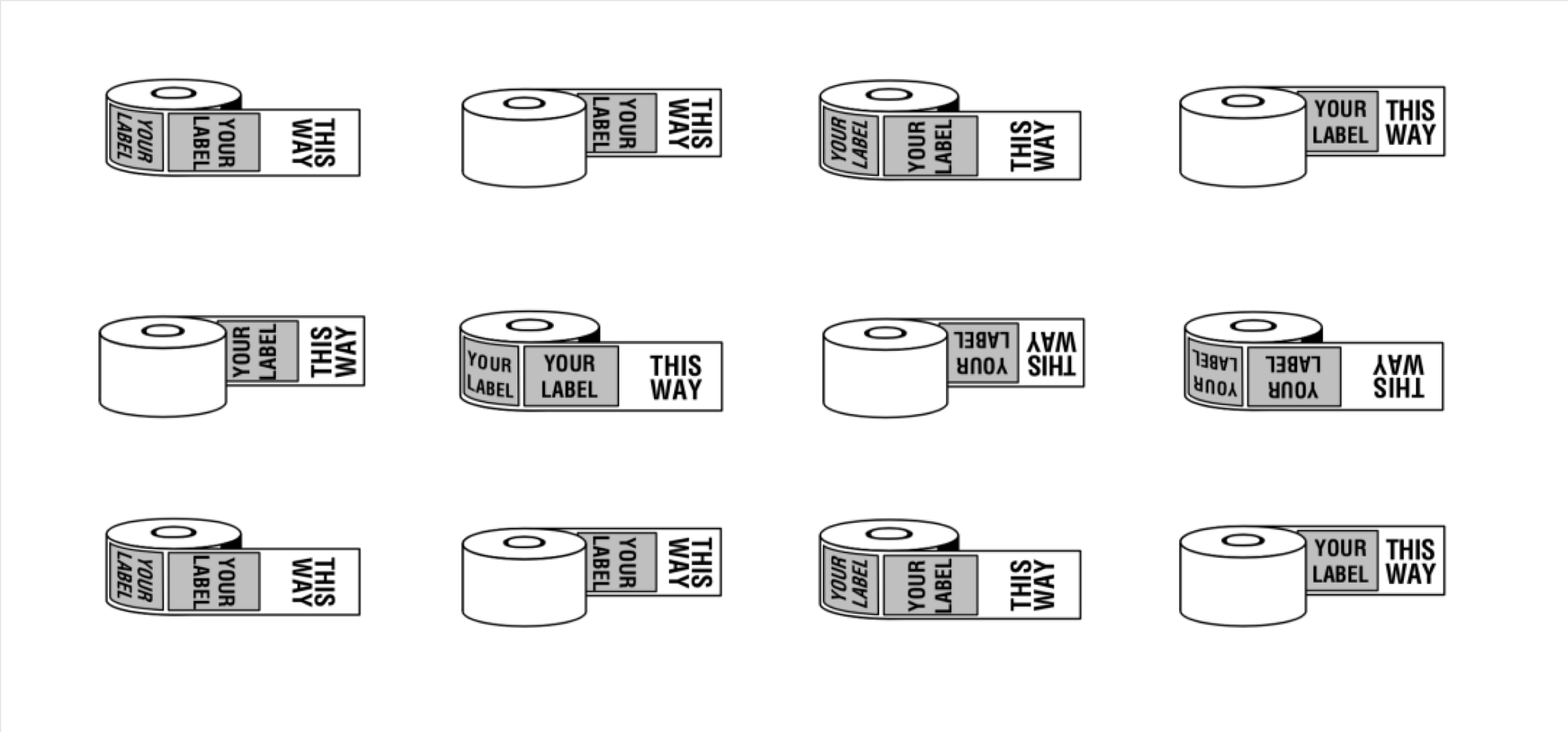

1.Rolling direction,

There are many kinds of running directions for the packaging machine,so if your printed roll film rolling direction cannot match your packing machine's,then everything will be wrong.It's important to confirm the rolling directiom,The rolling direction as following:

2.The thickness of the roll film that the packaging machine allows to pass.

Generally, packaging machines are designed to handle a range of film thicknesses, which is usually specified by the manufacturer. For example, a packaging machine may be designed to handle films with thicknesses ranging from 0.5 mils (0.0127 mm) to 10 mils (0.254 mm).

In any case, it is important to ensure that the film thickness being used is within the range specified by the packaging machine manufacturer to ensure proper operation and optimal packaging performance.

3.the Max weight of the roll the packing machine allows

Normally the max weight of the roll the packing machine can load is around 30KG,but it depends,so you have to figure out how much weight the packing machine can allows,then the packaging bags manufacturere can cut the rolls accordingly.

Beyin packing is a custom packaging bags manufacturer in China,specialized in design and producing custom packaging for more than 24 years,and we have professional sale tem to help you figure out the best custom packaging solution,so any question,please contact us.