Following the steps to custom your own snack packaging

Stand up pouches are the most popular bag type for snack packaging,like candy,chips,beef jerky,cookies,and fin seal bags are popular for chips packaging,and flat bottom bags are the premium packaging option for snack packaging.

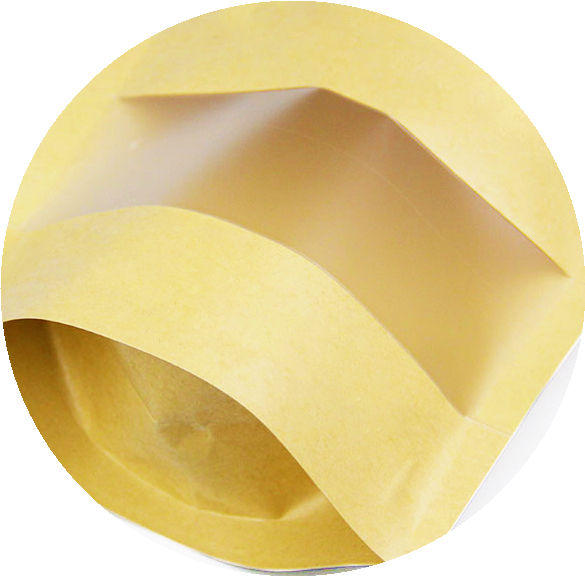

Stand up bags are with gusset bottom,after you filling in the product,the bottom will be opened,and support the whole bag stand up on the table firmly.

Flat bags are the bags made by front and back two panels ,three sides are heat sealed,only leave the one opening to fill in the product,popular for beef jerky packaging and small packaging.

Fin seal bags are the bag heat sealed at middle of bottom,situable for chocolate bar wrap and chips.

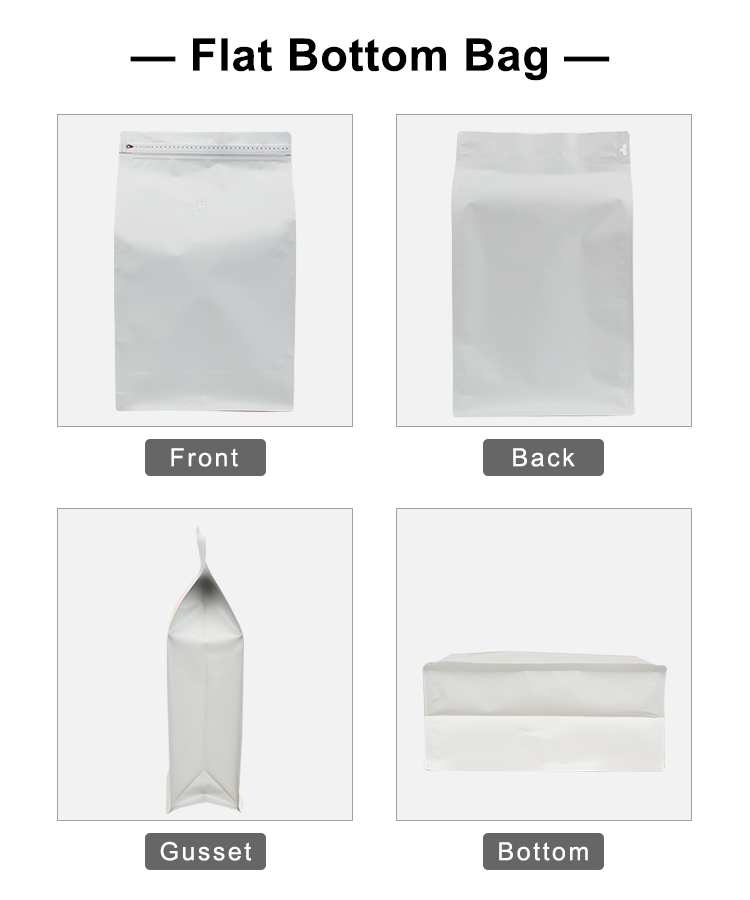

Flat bottom bags are kind of premium packaging,with the box bottom,it can stand up on the table firmly,and more panels to show brand and product information.

Side gusset bags have four panels,front,back and two sides.

The bag size can be customized,and depending on the different bags capacity and bag type,the bag sizes are different.Here's some popular bag sizes for your reference

| Bag Size | Bag Type | Bag capacity | |||

| Nuts | Gummies | Beef Jerky | chips | ||

| 10×15+6cm | Stand up pouches | 40g | 40g | ||

| 13×21+8cm | Stand up pouches | 130g | 100g | 30g | 80g |

| 15×23+8cm | Stand up pouches | 200g | 180g | 50g | 100g |

| 18×26+8cm | Stand up pouches | 500g | 480g | 60g | 120g |

If you still cannot decide your bag size,please contact with our sales team.we will recommend the bag size based on the bag capacity you need.

Snack packaging bags are all laminated with couple layers of film, to ensure the firmness of the packaging. The whole package has high mechanical properties, which can resist external pulling, friction and puncture, and protect the products in the package from damage.

The innermost layer of the package is a food-grade film, which can ensure the safety of food. The outermost layer film need to be printable.and with high mechanical properties. If the product needs to be protected from light, a layer of aluminum foiled film will be added inside the package. Aluminized film to achieve partial or complete protection from light, thereby extending the shelf life of the product.

The custom snack packaging bags can be matte finish and glossy finish,and UV prinitng is also avaliable so that the packaging can be matte fininsh and glossy finish.

Custom snack packaging bags can be designed with zipper,clear window,tear notch,hang hole,and handle.

Zipper

Clear window

Tear notch

Hang hole

Create a design that accurately represents your brand and appeals to your target market. Consider factors such as color, graphics, and text.

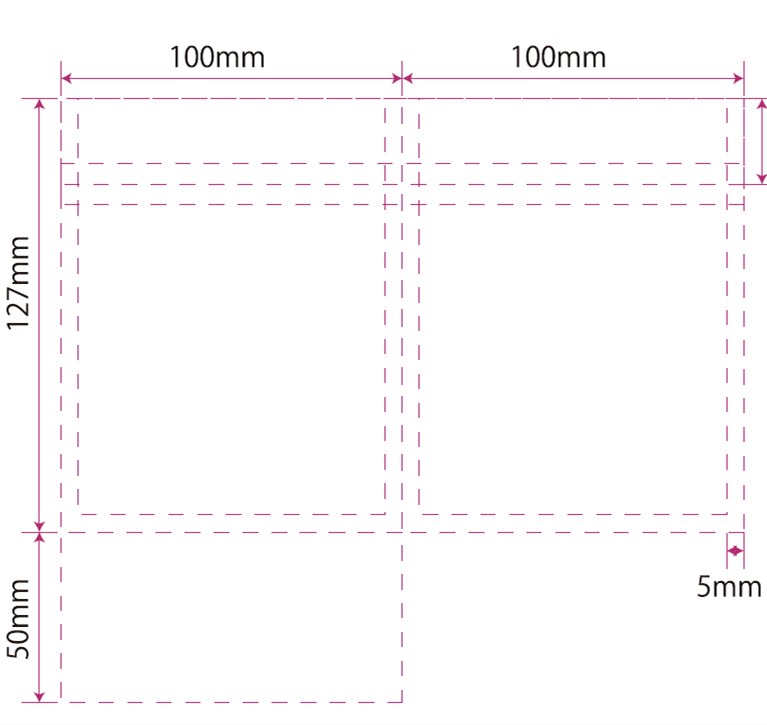

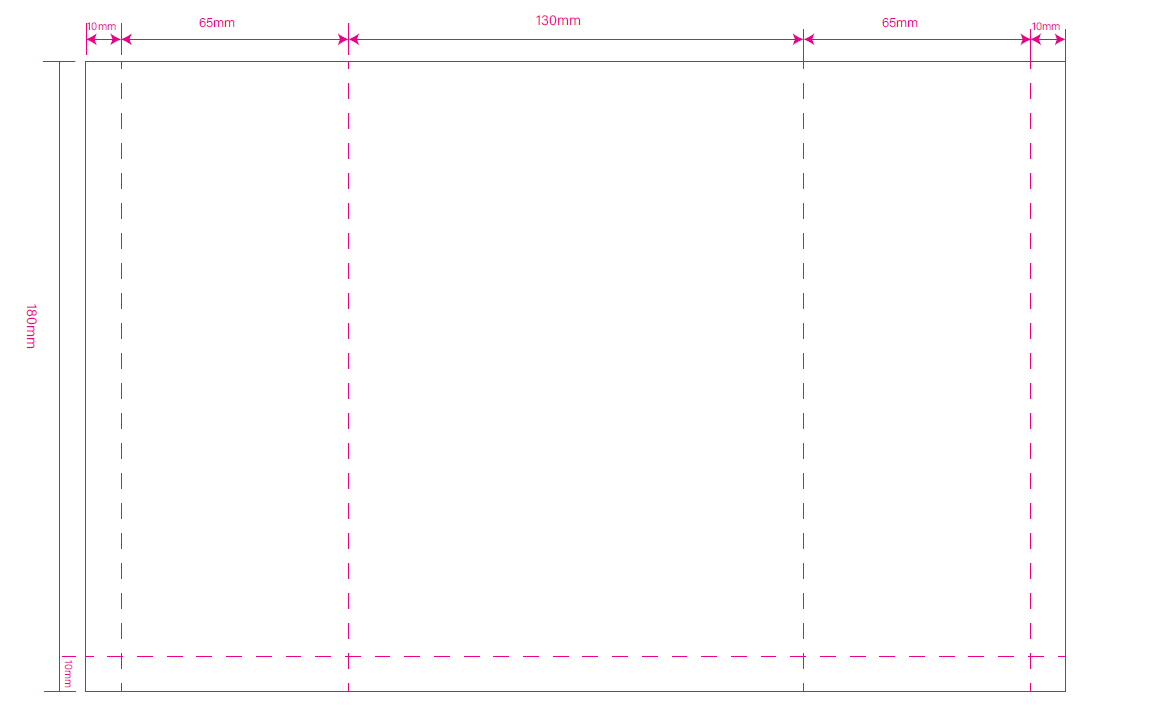

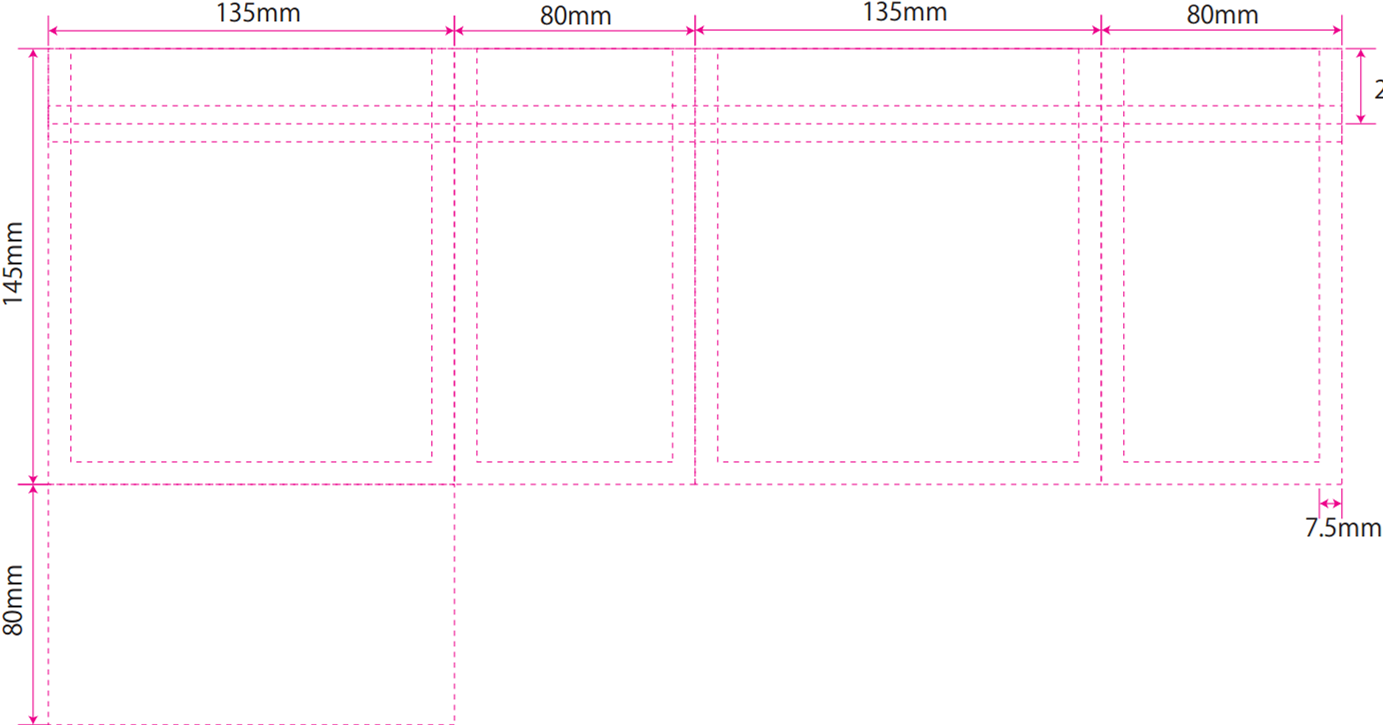

And Here's some die-line of different bag types for your reference.

Stand up pouches

Fin Seal Bags

Flat Bottom Bags

We can provide with free design if you need.

Find a printer who specializes in printing food packaging and can provide high-quality, food-safe printing.

Beyin packing specialized in producing custom packaging bags for more than 24 years,and we have exported to USA,Canada,Europe,UK, Saudi Arabia,and so on.We can produce the packaging bags printed with your logo and design.

We have digital printing and rotogravure printing.

Digital printing is suitable for small batch printing, MOQ is 1000pcs, the printing quality is very good, and the printing preparation is simple, so the lead time will be very short.

Rotogravure printing is suitable for mass printing,MOQ is from 10,000 to 100,000pcs based on bags size. The printing quality is more stable and the color is more restored. The price is several times lower than that of digital printing, but the preparation work is more complicated, so lead time are slightly longer.

The bags will be packed in cases and delivery to you,you can choose the bags delivery to you by DHL,Fedex,UPS,air,train and sea.

If you need,we can take care of the custom clearance by air or by sea.

After receiving the packaging bags,and before mass production, test the packaging to ensure it meets your expectations and requirements.Then you can fill the packaging with your snack, seal the packaging properly to maintain freshness and add necessary labels, such as EXP data,batch No. and so on.

WHO WE ARE

Beyin packing is a manufacturer in China ,specialized in printing and producing packaging bags for more than 20 years.Our customers are from more than 20 countries,including USA,Canada,UK,Germany,France ,etc.We have more than 20 production lines,and more than 50 technicist.The integrated quality control procedure systematically control each process,to ensure the product quality.

We have rich experience to help you custom your own packaging bags,from bag type,material,feature,bag size recommendation,and bag artwork design.Our pcakging bags placement reference including coffee bags,tea bags,candy bags,cookie bags,chocolate bags,chips bags,popcorn bags,jerky bags,cannabis bags,nuts bags,dried fruit bags,pet food bags,baking powder bags, protein powder bags,spice bags,vacuum bags,drink pouches,wine pouches,baby food pouches,lawn and graden product bags,clothing bags,mask bags.make up tools bags,and so on.

Our Service

All you need to do is tell us your product

Depending on your product,Beyin packaging can provide custom packaging bags solution for free,we can recommend the suitable material,based on the bag capacity ,we can advise the bag size and suitable bag type,we also will remind the user-friendly design on the bag.

Based on your requirement,we can provide free design,or die-line for you design the artwork on.

Based on the quantity you need,we can recommend the different printing methods ,which can solve the MOQ problem.

After finish the production,we can take care of the door-to door transportation,and you just need to stay at your place and waiting for your own brand bags.