Eco friendly flexible packaging is always the direction of Beyin packing’s efforts,,

As far, Beyin packing can produce biodegradable flexible packaging and 100% recyclable flexible packaging.

Two ways of eco-friendly flexible packaging

Environmental packaging has always been the hottest topic recent years. Everyone has promoted that their products are environmentally friendly products. However, the current environmentally friendly packaging materials are still intricate and the standards for environmentally friendly packaging are not mature and unified. It can be said that everyone is still in the groping stage. . At present, the more mature environmentally friendly materials are PLA materials and corn-based plastic film, but most of these environmentally friendly materials are used in single-layer packaging ,just like shopping bags with simple structures, and they are not successful in the application of multi-layer laminated flexible packaging bags. Then how to achieve environmental protection for multilayer plastic packaging?

After years of exploration and research, Beyin packing has taken a big step towards the success of environmentally friendly materials for multilayer plastic packaging. The biodegradable packaging bags and 100% recyclable packaging bags launched by Beyin Packing will be introduced below.

BIODEGRADABLE FLEXIBLE PACKAGING

Most of the shelf packaging bags are laminated by multiple layers of plastic film, so as to strengthen the toughness of the bag, effectively protect the products in the packaging bag from damage during transportation, and can be beautifully printed as well as achieve food-grade safety.

As far, most of the corn-based degradable materials and PLA degradable materials on the market can only be applied to single-layer packaging bags, such as shopping take away bags. They cannot be applied to multi-layer plastic packaging. Then how make the mutilayer flexible packaging bags eco-friendly?

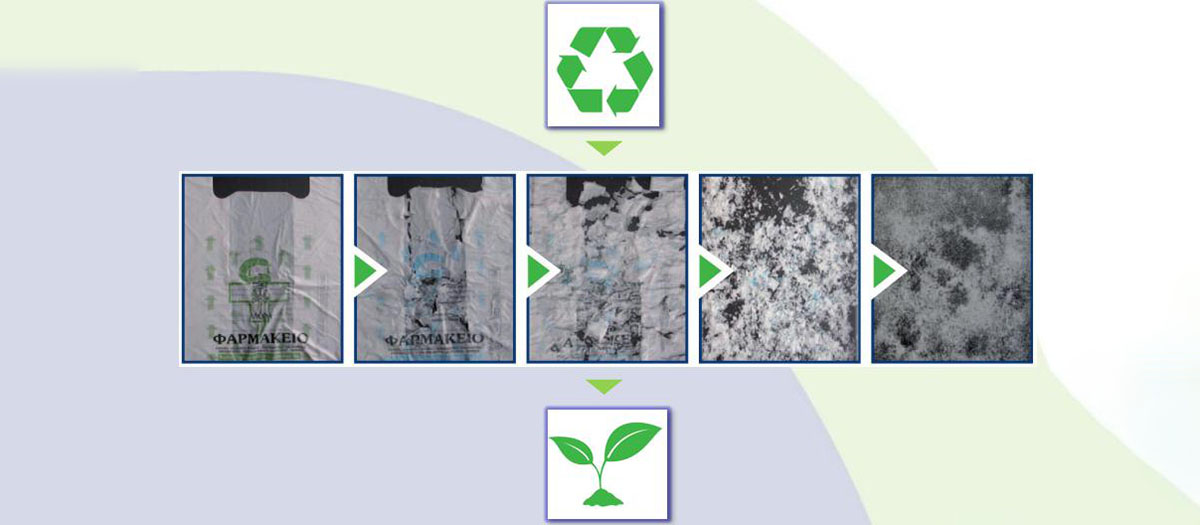

After years of exploration and experimentation, Beyin packing have discovered a masterbatch that can be directly applied to plastic film to directly degrade the plastic film into tiny particles that can be absorbed by microorganisms. No matter what kind of plastic, just add this masterbatch to degrade your plastic into particles that can be decomposed by microorganisms. In this way, no matter your packaging is composed of several layers of plastic film, it can be degraded.

After the used plastic bags being discarded, the polymer with long carbon chain structure first reduces the molecular weight through oxidative degradation, which leads to brittleness, which is also a necessary condition for the second stage of biodegradation; under the action of microorganisms, these small molecules are finally converted into water, carbon dioxide and biomass. One of the most notable features of "Reverte" technology which is the masterbatch Beyin packing using is that it contains a unique catalyst controllable composition that can delay the degradation process of the bag. The degradation only begins when the bag and film have been used up and after sufficient light has passed. Therefore, even if the bag and film are stored in a hot warehouse for several months before use, there will be no change. Since only a small amount of "Reverte" needs to be added in the production process, the cost increase of bags or films with "Reverte" added is not significant compared with ordinary non-degradable bags or films. Various types of "Reverte" have passed the FDA and EU EC food safety contact regulations certification, so they can be used in the field of food packaging.

100% RECYCLABLE FLEXIBLE PACKAGING

Since mutilayer plastic packaging are made of different plastic films, such as PET, PE, PA, etc., although each layer is individually recyclable, when they are combined together, it is difficult in practice to peel off the films and recycled.

However, the 100% recyclable packaging bag launched by Beiyin Packaging is also mutilayer packaging bags, but the outer layer and the inner layer are both composited by PE plastic film.

PE is generally used as the inner layer of mutilayer packaging bags, because it is a food-grade film and has better heat sealability, which can help heat seal the packaging bag, but PE is generally not used as an outer film because of its The stiffness is not high enough to support the standing of the entire bag, and the puncture resistance and impact resistance are no better than other films. However, although the BOPE used by Beiyin Packaging is also a kind of PE, due to its special process, the puncture resistance and impact strength of BOPE are more than 2 times higher than that of ordinary PE, and the stiffness is better than ordinary PE. It can completely replace PET and PA plastic films used in the outer layer. In this way, the packaging bag made of BOPE/PE composite is not only strong and rigid, but also because it is composited with PE film, the entire packaging bag can be recycled as pure PE.

BAG TYPE OF ECO-FRIENDLY FLEXIBLE PACKAGING

The biodegradable flexible packaging and 100% recyclable flexible packaging made by Beyin Packing can be customized in printing and size, and can be applied to a variety of bag types, such as stand up pouch,side gusset bags,flat bottom bags,flat bags,fin seal bags,and so on.

stand up pouch

Flat bag

Side gusset bag

Flat bottom bag

Beyin packing has specialized in design and producing custom packaging bags for more than 23 years,we have rich experience,and mature team to help you on the packaging bags for various of product,so if you have any question about packaging bags,feel free to contact us.