Stand up Zipper Pouch for Rice and Flour Packing

Flour packaging bags are different, depending on the weight of the flour loaded, the type of packaging used is different, for example, 20kg, 50kg mostly use woven bags or non-woven bags, or woven and kraft paperlaminated packaging bags , The sealing is sewn up with thread. And if you need a small-capacity flour packaging bag that can be displayed on the shelf, you can consider a packaging bag made of plastic or kraft paper. Generally, this packaging bag is suitable for small-capacity flour, such as 10lbs, 5lbs ,1kg 500g 250g 100g,and Beyin packing can produce this kind of flour bags.

We all know how important role the packaging bags play in product sales for a brand. Even for products of the same quality, different packaging needs to be designed according to different sales positioning and sales strategies. The quality of the packaging bag, including the eye-catching design, the touch and cleanliness of the packaging bag, the details of the packaging bag, and the color reduction have greatly affected consumers' perception of the brand.

Even more,a good packaging bag represents good product quality and high sales volume. Therefore, choosing a packaging bag supplier with good quality and stable supply is an intuitive and important part for the brand.

Now you wanna design a flour packaging bag,let’s learn more about it.

What are the flour packaging made of?

As a kind of food packaging bags, flour pouches are made of a variety of plastic films or paper or aluminum composites, so as to ensure the firmness of the bag and the safety of the food. The flour packaging bag can be composed of two layers, three layers, and four layers. Let's take a closer look below.

Two layers flour packaging

Two-layer flour packaging are generally made of PA/PE laminated, or PET/PE, PET/CPP, PA/CPP, PA is also commonly known as nylon, and it is mostly used as the outer layer of large-volume packaging bags because of its mechanical strength is high, toughness is good, and strong, while PET is more economical and affordable. CPP is mostly used for the inner layer of packaging bags that require better transparency, or the inner layer of food packaging bags that require special treatment,like retort.

Three layers flour packaging

a. This three-layer flour bag is made of BOPP/PET/PE. Generally, the plastic flour bag with matte surface you see on the market, and if the bag is relatively flat, it is usually made of this material.

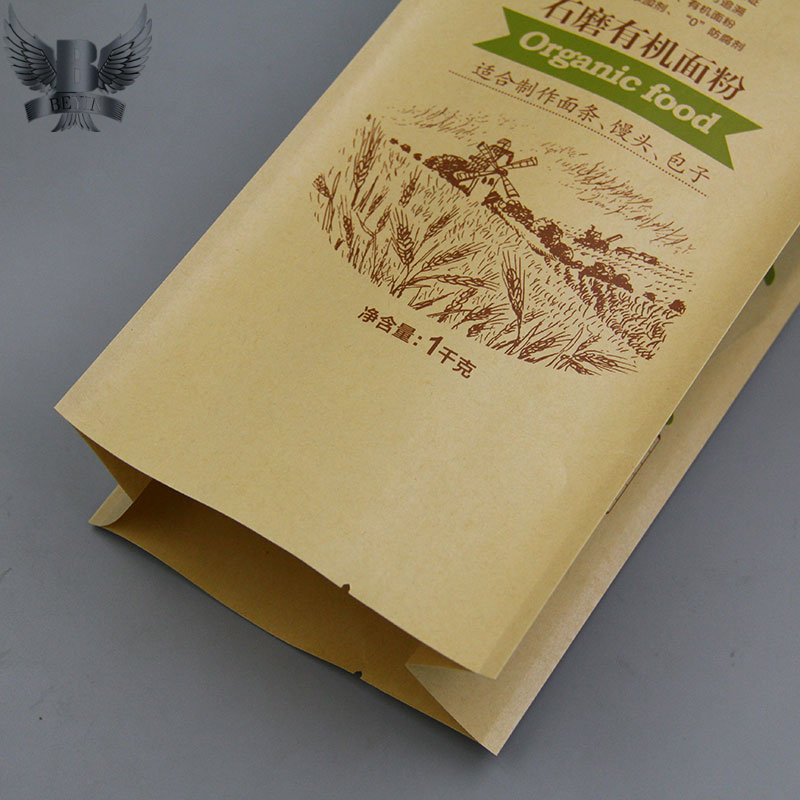

b. This three-layer flour packaging is made of BOPP/PAPER/CPP . Although it looks like just a paper packaging bag, but because the paper is a material that is easy to be ripped during transportation, it still needs to be laminated a layer of plastic film as outer layer, and in order to protect the safety of food, and improve the barrier of moisture and oxygen, the inner layer of paper is often laminated with a layer of CPP or PE plastic film.

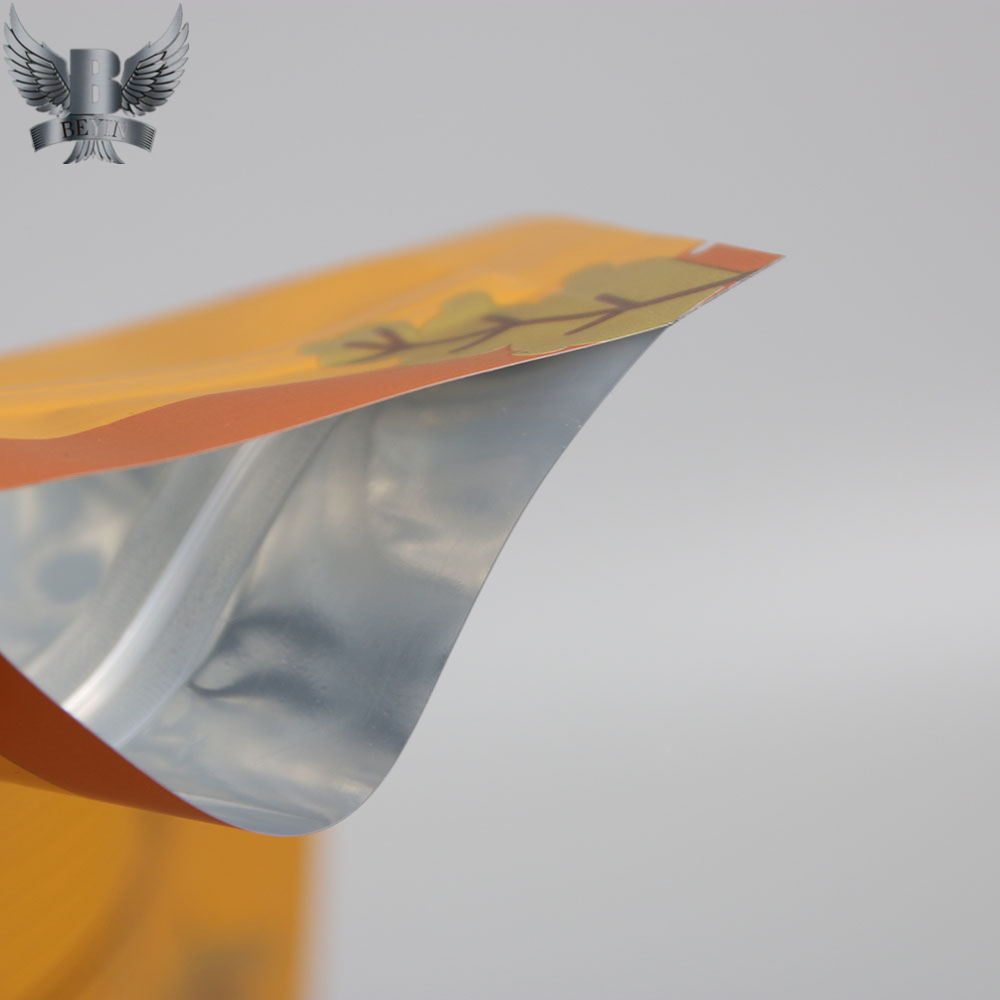

c. This is also a three-layer flour packaging. You can see that the packaging bag has a silver layer. This type of packaging bag is generally made of OPP/VMPET/PE , or PET/VMPET/PE ,the silver layer inside is the aluminum foiled layer, which can block light and moisture and oxidation better. For packaging bags that require a higher level of protection, we generally recommend this structure. If it is required to completely avoid light, oxygen, and moisture, we will recommend the use of pure aluminum. Instead of aluminum foil.

Four layer flour packaging

The structure of four-layer flour bags is mostly used for paper bags. For example, if customers need paper packaging bags as well as have high requirements for light and moisture and oxygen insulation, we will recommend BOPP/PAPER/VMPET/PE four layers laminated packaging bags, or when customers need paper packaging bags with small clear window, in order to protect the products in the packaging bags at the window area, we also recommend using BOPP/PAPER/PET/PE laminated packaging bag.

Because flour is a powdery substance, static electricity is often generated during machine packaging, which will adsorb the flour on the seal and affect the sealing effect. Therefore, in order to solve this problem, we generally recommend using anti-static PE film as the inner film of the flour packaging bag. If you have any special requirements, Beyin Packaging can do all for you.

All of the above are flour packaging bags with common structures on the market. Of course, there are some flour packaging bags made of special film composites, such as the following laser packaging bags and drawing packaging bags.

What are the types of flour packaging?

The common flour packaging types in the market include flat bags, stand-up bags, side gusset bags,etc.

Flat bags: except for the opening, the other three sides are sealed. This type of bag is often used to hold large-capacity flour, such as the capacity of 1KG or more. Add a handle on the top of the bag so that consumers can easily carry it away.

The stand-up bag is also a very popular food packaging bag. It can stand on the shelf for display purposes. It is generally used to hold 500g flour or less.

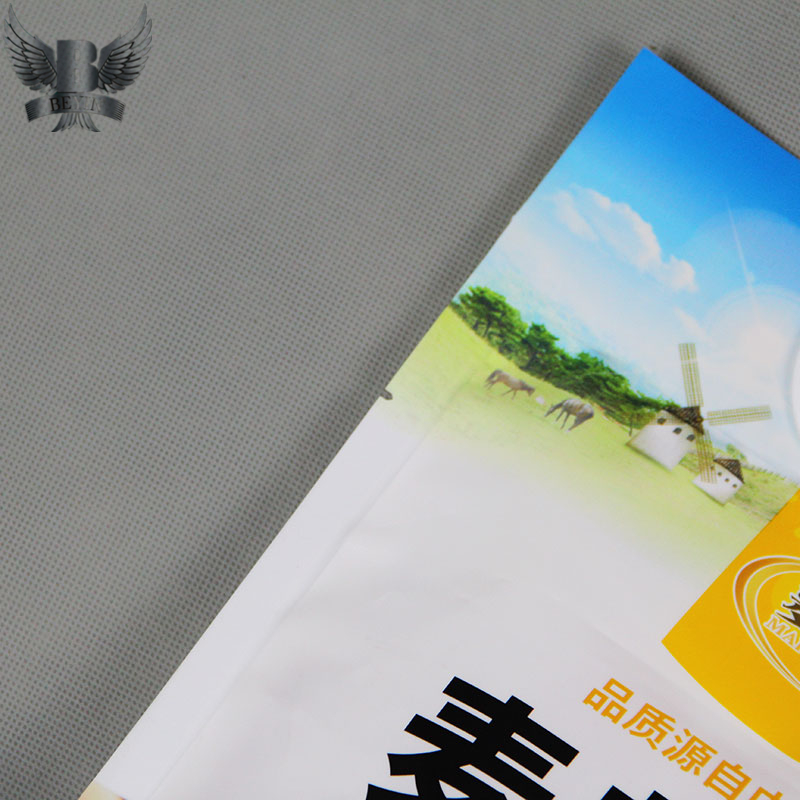

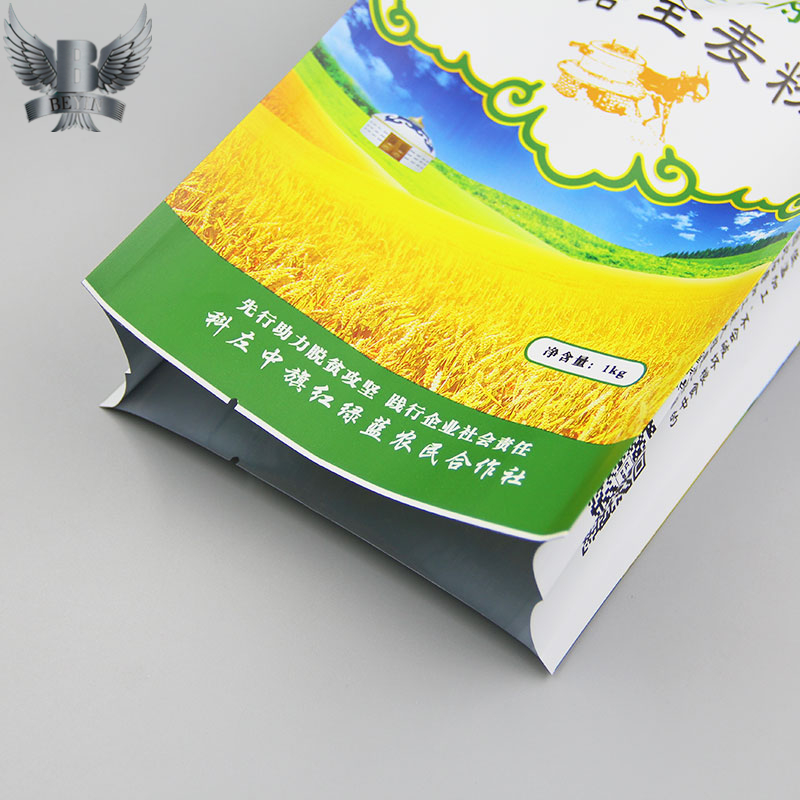

The side gusset bag is also called a Quad bag. After the product is filled, the whole package looks square, very neat and beautiful.

The size of the flour packaging

The packaging sizes of flour bags of different capacities and different bag types are different. The following are some of the sizes of flour bags we recommend:

| Capacity | Bag Type | Bag size |

| 500g | Stand up bags | 18×28+8cm |

| 500g | Side gusset bags | 13×26×7cm |

| 1Kgs | Side gusset bags | 17×30×6cm |

| 1Kgs | Stand up bags | 22×28+8cm |

| 2Kgs | Side gusset bags | 21×37.5×7cm |

| 2Kgs | Stand up bags | 23×30.5+12cm |

| 2Kgs | Flat bags | 27.8×40cm |

| 5Kgs | Flat bags | 32.7×52.8 |

| 5Kgs | Side gusset bags | 25×53×12cm |

Please be attention that before placing an order of flour bag, you must actually load the product to verify whether the size recommended by the sales is suitable for your product, and then adjust the size according to the packaging effect.

The price of flour packaging?

The price of the flour bag varies according to the size, bag type, thickness and special requirements of the flour bag. Please inquire about Beyin packing sales in detail. You can email mialee@foodpackingbag.com. or whatsapp +1 213 461 8535. We will immediately reply to you.

What is the minimum order quantity of custom flour packaging bags?

The MOQ of customized flour bags is determined by the bag type and size of the flour bags, generally ranging from 10,000 to 50,000pcs.

How to produce flour packaging bags?

After confirming the artwork, we will arrange the purchase of raw materials. According to the structure, size and thickness of the bag, we will count the types and quantities of raw materials used, contact the supplier to place an order, and the suppliers that Beyin packing cooperates with are all certified by the ISO system,can supply good quality stably. At the same time, we will contact the cylinder manufacturer to start making cylinder rollers in different colors according to the customer’s artwork. Each color with a cylinder roller. The cylinder roller is used to print the customer’s artwork on the bag, so it is usually involved in the quotation. The cylinder charge is used to make the cylinder rollers.

After the raw materials are in placed in about a week, our QA will inspect the incoming materials , including whether the raw materials are damaged, whether the technical parameters such as size, thickness, and tension are qualified, after inspected the material can enter the production preparation stage.

After the cylinder rollers is made, the color sample will be printed to the customer for confirmation. After the color and design are confirmed, the production will start.

First print, install the cylinder rollers on the printing machine, and print the customer's artwork on the outer film in different colors. Beyin packing uses 9-color high-speed printing machine, which can print 220 meters per minute at the fastest. Environmentally friendly ink, without BPA, it can restore the vividness of colors to the greatest extent.

After printing, the next step is laminating. Each layer of the packaging bag is laminated together with a laminating machine. After laminating, it will be strengthened and firmed in the soliding room ,and eliminate odors.

The last step is to cut the film rolls into bags according to the bag type.

We will inspect finished packaging bags before packing,include material,size,thickness,tensile strength and so on.

All of our packaging bags will be packed in a stack of 50 in a carton, which is convenient for transportation and can protect the products inside from damage.

Beyin Packaging was established in 1998 and has been specialized in the design and production of packaging bags for more than 20 years. Here, you can get the most professional advice and services, and we can also provide free packaging design.

How to open the flour bag?

We will make an tear notch on the side of the flour bag, from here you can tear the bag easily.

How to seal the flour bag?

Some flour bags will have a zipper, which can be sealed repeatedly.

How to store flour bags?

a. Because flour bags are greatly affected by temperature, remember to try not to place them in a place where the sun can be directly exposed, because strong ultraviolet radiation will accelerate the aging of the flour bags.

b. The flour bags must avoid extreme heat and cold as much as possible, so as to prevent the flour bags from thermal expansion and contraction and shorten the life.

c. Remember not to put the flour bags in a damp, airless place, it is easy to rot the packaging bag and affect its use.

d. For some flour bags that have not been used for a long time, be sure to check them carefully for cracks before starting to use them.

Is the flour bag compostable?

Beyin packing can produce degradable flour packaging bags,the material we used can help degrading the plastic to the tiny molecules which can be decomposed by microorganism